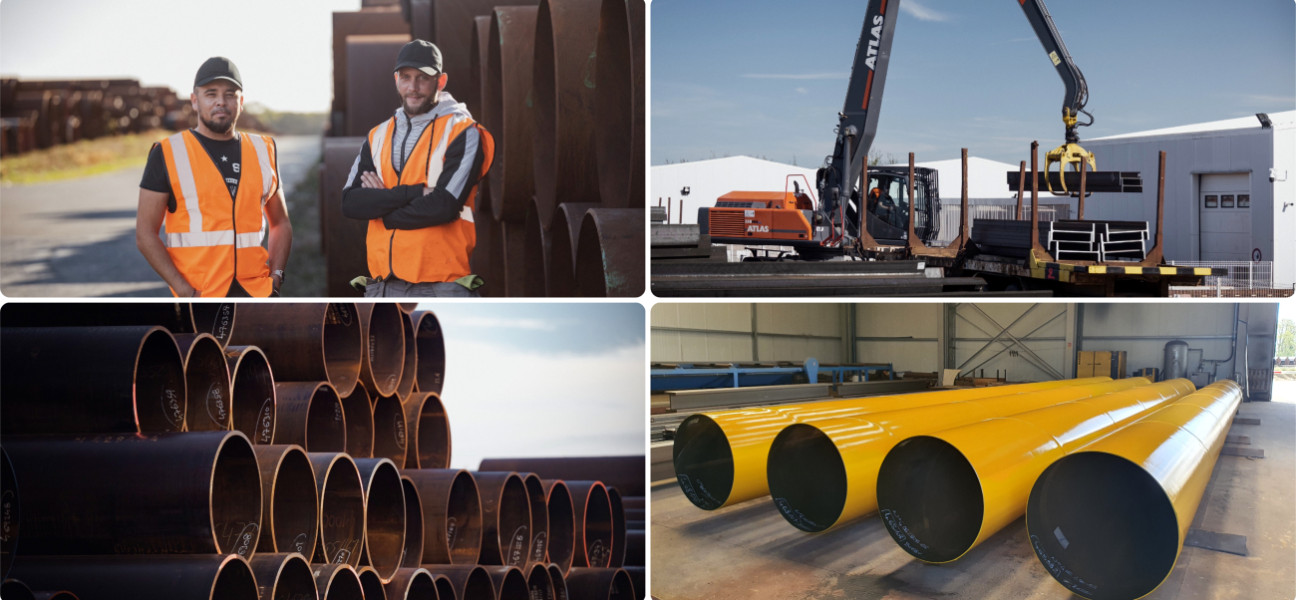

150 000 tons in stock. 12 service workshops. 50 years' experience.

Specializing in the distribution and processing of steel pipes, tubes & beams, STAD supplies the European construction market since 1972. With over 150 000 tons of steel pipes, tubes and beams in stock at our Avrigny site in France, we have the most comprehensive range available to meet all your requirements. Thanks to our 12 on-site finishing workshops, we can deliver finished, ready-to-use products as quickly as possible, directly to your site or worksite.

Steel Pipes & Tubes: 100 000 tons in stock

Type: Long welded (ERW, LSAW), spiral welded (HSAW) and seamless tubes

Diameters: Ø 48mm - 2200mm (from 2” to 90”)

Thickness up to 50mm (2”)

Norms / Standards: EN 10219 in S235JRH - S355J0H - S355J2H - S460MH steels with 3.1 + C.E. and D.O.P. certificates or API in X52 - X60 - X65 - X70 steels. or EN10217 in P235GH - P265GH steels. Or second choice without certificates.

Services: Saw cutting up to Ø 813 mm, gas cutting up to 2200mm. Welding of all diameters and transportable lengths. Shot-blasting and painting up to Ø 1422 mm.

Steel beams / sections: 50 000 tons in stock

Steel beams / sections :

HEA / HEB / HEM up to 1000.

IPE up to 750.

W / HL / HP / IPN / UPE / UPN / Angles.

Norms / Standards: EN 10025 steel S275JR and S355J2. Certificates 2.2 or 3.1 + C.E. and D.O.P. Or second choice without certificates.

Services: Cut to length (straight or angled) on all profiles, drilling, shot-blasting, painting, etc.

[Read more]

Cut to length:

We can cut to length our pipes, tubes and beams to suit your requirements at short notice: saw-cutting of all our tubes up to Ø 813 mm and all our beams (including bevel cutting and drilling) up to HEM 1000. Oxycutting for all tubes up to Ø 2200 mm, including the creation of oxycut chamfers to enable subsequent welding.

[Read more]

Welding and jointing

All our tubes up to Ø 2200 mm can be welded at your request in lengths of up to 36 meters (ultrasonic welding, etc.).

Sheet pile keys (#C9) or pile heads can also be welded, as can any other accessory you may require (handling lugs, etc.). The aim is to deliver a finished product on time, and avoid costly finishing touches on your site. We have a team of qualified ultrasonic welders at your disposal, and we can arrange for welds to be inspected by external inspection bodies at your request.

[Read more]

Paint & shot-blasting customized to your needs

ACQPA-certified paints, including marine anti-corrosion, and epoxy paints.

Our ACQPA-qualified painters can paint our pipes, tubes and beams to your specifications (IM2 H marine paint, etc.).

We also offer a shot-blasting service for tubes up to 1422mm, and beams up to HEM 1000.

Please do not hesitate to contact us to discuss your requirements.

Metal Fabrication

To meet the needs of increasingly complex worksites such as the Grand Paris Express, we have built a complete 5000 m² fabrication workshop, equipped with two 15-ton overhead cranes, enabling us to produce finished fabricated welded elements such as props, struts, and bollards onsite.

Do not hesitate to contact us with your plans, so that we can study the feasibility of your project.