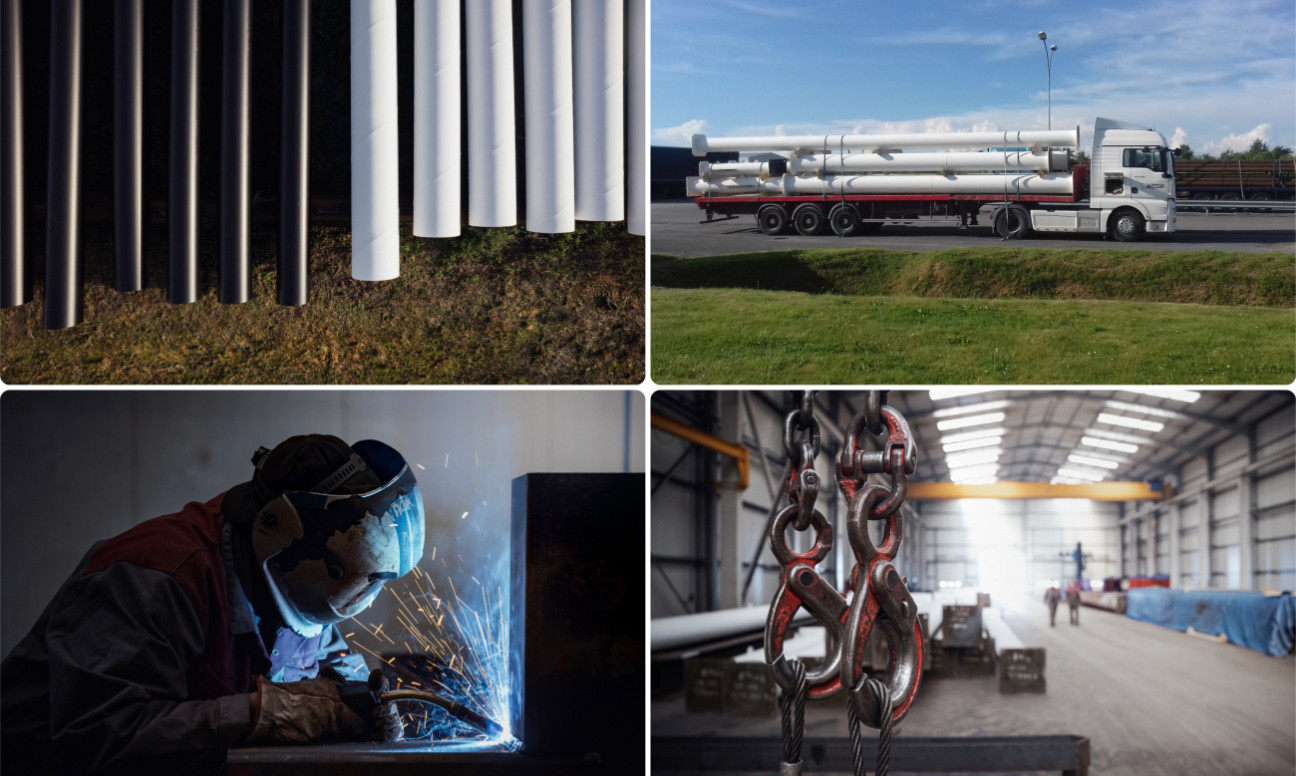

11,000m² of on-site workshops for a customized service.

With over 50 years at your side, we've seen your needs evolve. Nowadays, you want to receive a finished product on site, as quickly as possible, so that you can minimize your intervention times and control your costs. With this in mind, our range of services has evolved with your needs. We have a number of on-site cutting, welding, shot-blasting, painting and fabrication workshops, enabling us to respond rapidly to all your requests and offer you a made-to-measure service. We can also organize all types of special transport, and call on the services of approved external inspection bodies.

Cut to length:

We can cut to length our pipes, tubes and beams to suit your requirements at short notice: saw-cutting of all our tubes up to Ø 813 mm and all our beams (including bevel cutting and drilling) up to HEM 1000. Oxycutting for all tubes up to Ø 2200 mm, including the creation of oxycut chamfers to enable subsequent welding.

Welding and jointing

All our tubes up to Ø 2200 mm can be welded at your request in lengths of up to 36 meters (ultrasonic welding, etc.).

Sheet pile keys (#C9) or pile heads can also be welded, as can any other accessory you may require (handling lugs, etc.). The aim is to deliver a finished product on time, and avoid costly finishing touches on your site. We have a team of qualified ultrasonic welders at your disposal, and we can arrange for welds to be inspected by external inspection bodies at your request.

Paint & shot-blasting customized to your needs

ACQPA-certified paints, including marine anti-corrosion, and epoxy paints.

Our ACQPA-qualified painters can paint our pipes, tubes and beams to your specifications (IM2 H marine paint, etc.).

We also offer a shot-blasting service for tubes up to 1422mm, and beams up to HEM 1000.

Please do not hesitate to contact us to discuss your requirements.

Metal Fabrication

To meet the needs of increasingly complex worksites such as the Grand Paris Express, we have built a complete 5000 m² fabrication workshop, equipped with two 15-ton overhead cranes, enabling us to produce finished fabricated welded elements such as props, struts, and bollards onsite.

Do not hesitate to contact us with your plans, so that we can study the feasibility of your project.